Overview of Expansion Valves

Thermostatic expansion valves reduce the pressure of liquid refrigerant at high-temperature and high-pressure discharged from the condenser to a state where it can easily evaporate, ensuring the optimum flow rate in the evaporator.

Thermostatic expansion valves keep the superheat of refrigerant gas within a certain range in accordance with the capacity of compressor which changes as the cooling load increases or decreases and prevent abnormal heating and liquid return.

ITEMS TO BE DESIGNATED WHEN PLACING ORDERS

- 1.For standard models, please specify the catalog number.

- 2.For special specifications except standard models, please specify the following points.

- Normal Pressure, Minimum and Maximum Operating Pressure (Condensing Pressure, Evaporating Pressure)

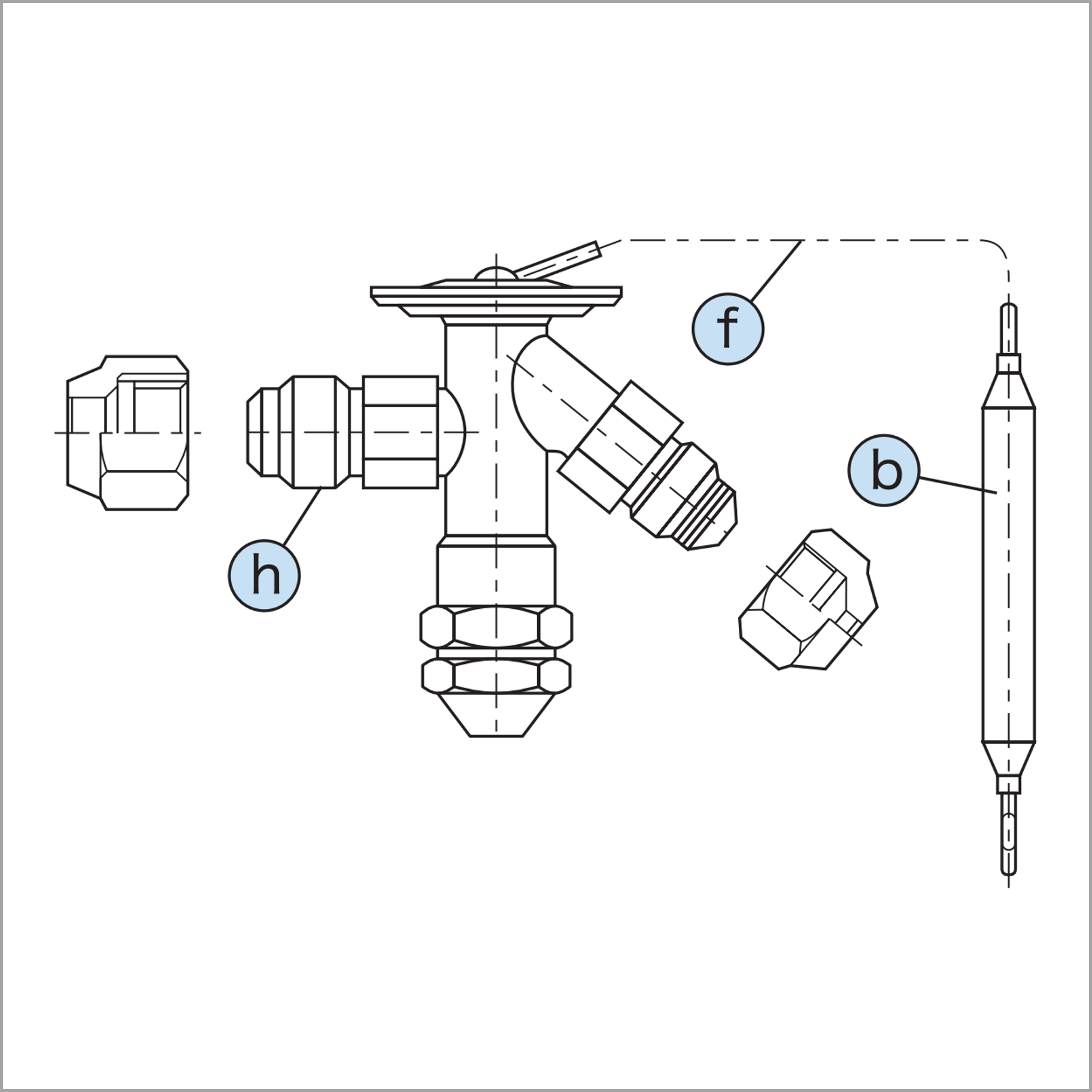

- Application, Charge Types…b

- Normal Temperature, Minimum and Maximum Operating Temperature (Condensing Temperature, Evaporating Temperature)

- Mounting location (Temperature of the mounting location at the body, sensing bulb, etc.)

- Cooling Capacity (With condensing temperature and evaporating temperature)

- Length of the Capillary Tube…f

- Refrigerant

- Connection type (Flare, Solder)…h

TERMS AND DEFINITIONS

- Catalog No.:

On standard products, specify the Catalog No. only. - Adjustable Range:

It is possible to set at any position within Adjustable Range. (Mainly based on a valve opening start position.) - Capacity:

Nominal capacity under standard operating conditions - Connection Type:

Flare connections mainly adopt flare pipe connections for refrigeration.

All dimensions are shown based on the piping side to be connected. - Max. Working Pressure:

The maximum usable pressure at which the valve will function without

any problems under normal operating conditions.

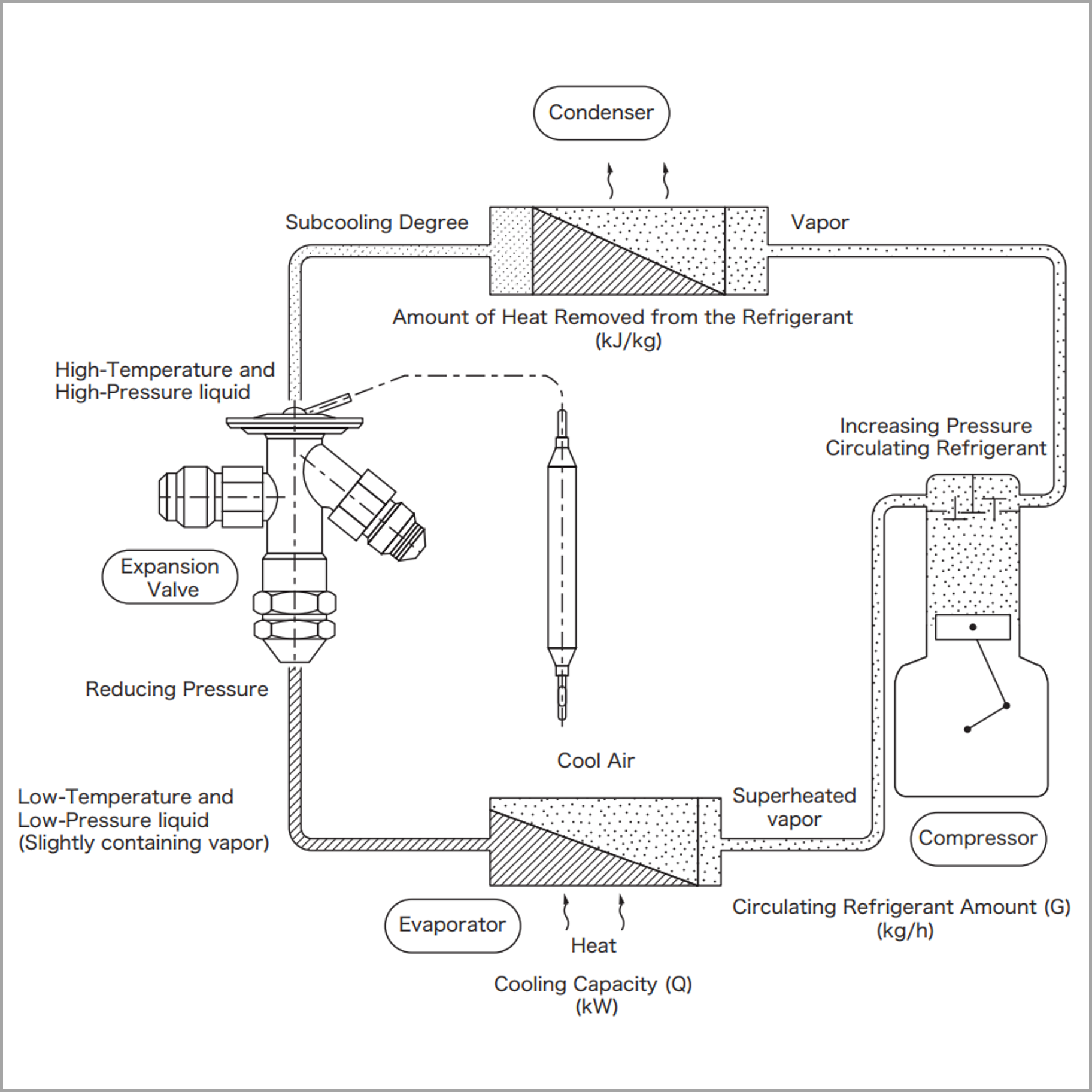

Relation between Expansion Valve and Refrigeration Cycle

Relation between Expansion Valve and Refrigeration Cycle

1.Condensing Temperature (CT)

The highest temperature of the liquid condition of refrigerant in the refrigerant cycle. (Temperature of saturated refrigerant liquid at the expansion valve inlet)

2.Evaporating Temperature (ET)

The temperature at mixture condition of refrigerant gas and liquid to cool water or air load etc.(Temperature of saturated refrigerant vapor at the expansion valve outlet)

3.Subcooling (SC)

The degree of temperature reduction, without changes of pressure, against the pressure equivalent to the refrigerant liquid temperature. (Difference between the temperature at the expansion valve inlet and temperature equivalent to the refrigerant pressure)

4. Superheat (SH)

The degree of temperature increase, without changes of pressure, against the pressure equivalent to the refrigerant gas temperature. (Difference between the temperature at the sensing element of the expansion valve and the temperature equivalent to the pressure at the equalizing section)

5.Condensing Pressure

The pressure equivalent to CT.

6.Evaporating Pressure

The pressure equivalent to ET.

7.Cooling Capacity

The amount of cooling heat in kW.

1 U.S. Refrigeration ton (U.S.R.T.) = 3.52 kW

8.Pressure Drop

The major cause of pressure drop is frictional resistance in piping. Pressure drop in the high-pressure side causes a reduction in the degree of subcooling or the generation of flush gas, while pressure drop in the low-pressure side causes temperature variance in the evaporator and a reduction in capacity. Pressure drop in the internal pressure equalized expansion valve leads to an increase of operating superheat.

9.Maximum Operating Pressure

The maximum pressure (designed pressure) at which the expansion valve functions without problems under normal conditions of use.

SENSING BULB CHARGING TYPE

It is necessary to select the most appropriate charging type in accordance with the type of refrigerant, evaporating temperature, thermal effect by defrost, ambient temperature of the mounting part, etc.

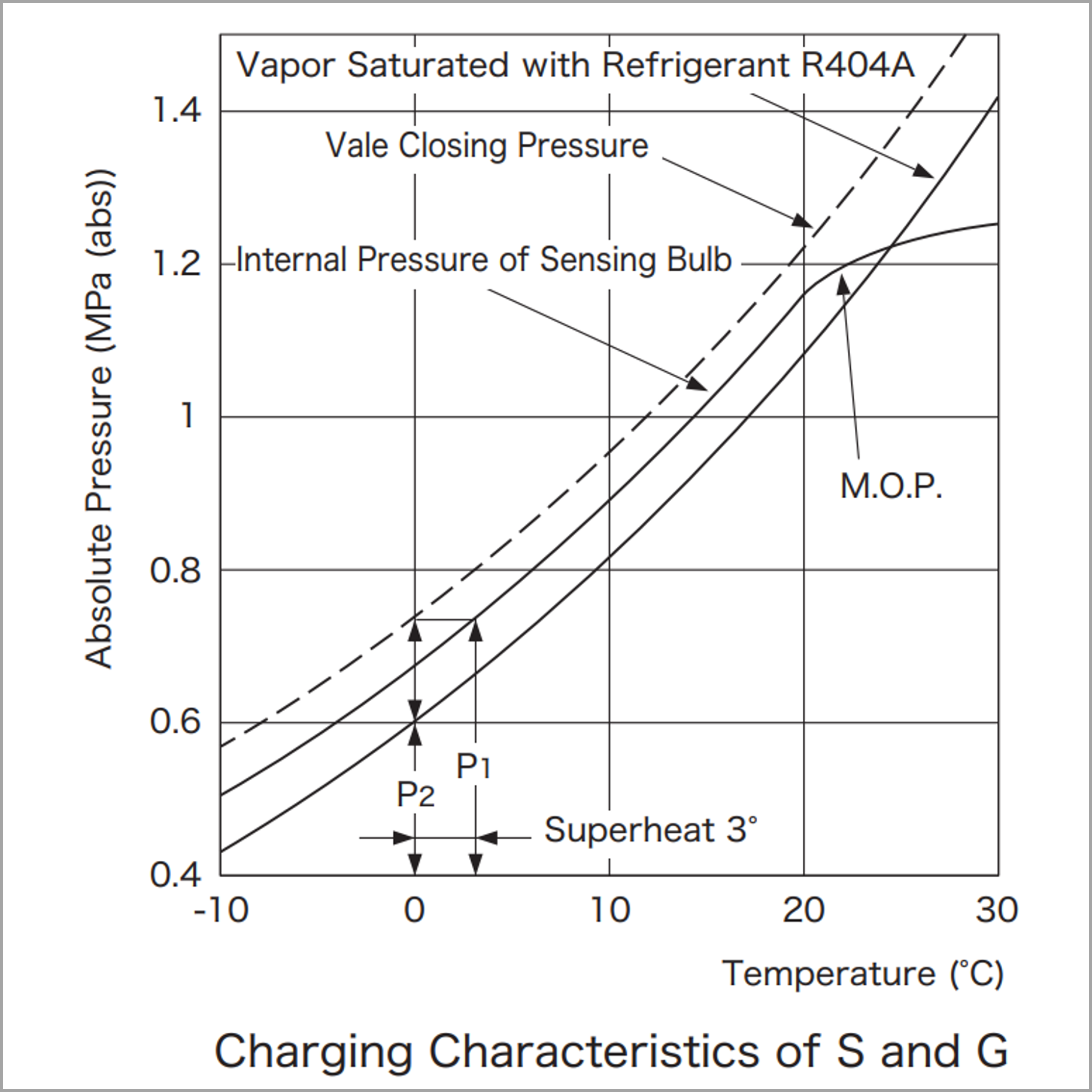

Charging Characteristics of S and G

Charging Characteristics of S and G

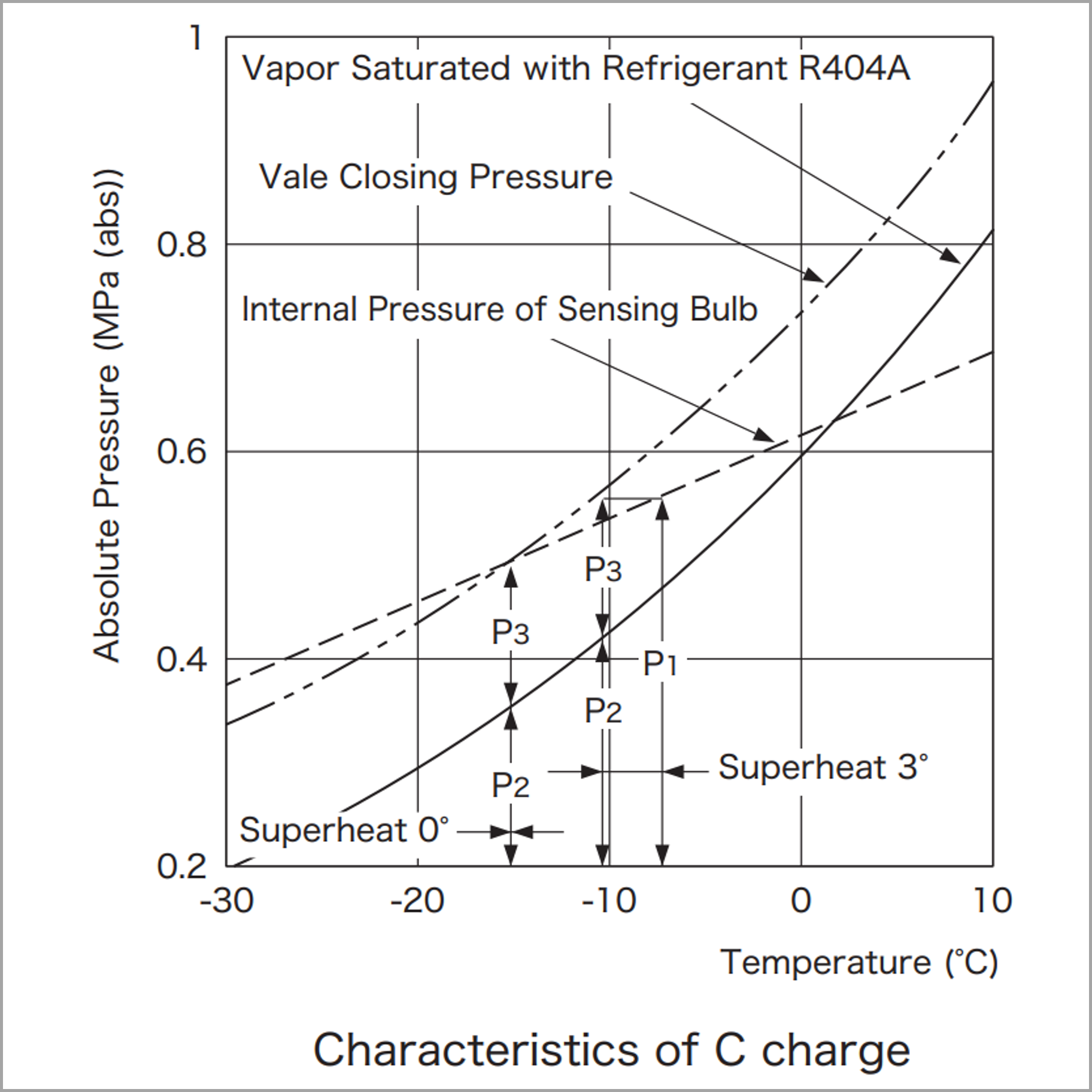

Characteristics of C charge

Characteristics of C charge

Special Charging Types (S) (SA) (SL)

Composed a mixture of different gases, minimize the operating superheat compared with charging type (G) and control the maximum operating pressure (M.O.P.).

・Symbols are changed in accordance with the difference in the applied range of evaporating temperature and M.O.P.

・Mainly for cooling units (protected horticulture), heat pump equipment, and low temperature equipment

Gas Charging Type (G)

The same refrigerant used for the equipment is charged, and there is a point at which charged liquid becomes superheated gas at the certain temperature rise. This point is called the maximum operating pressure (M.O.P.).

・Mainly for cooling units

Controlling M.O.P. enables to prevent liquid return at startup and to prevent overload of the compressor motor.

Special Charging Types (C) and (CL)

Adsorbent and special gas are charged. Using changes in pressure by high-temperature desorption and low-temperature adsorption, these types can minimize the operating superheat at low temperature condition. These types can be controlled correctly regardless of temperature difference between sensing bulb temperature and ambient temperature around the body. There is no control of M.O.P.; however, overload prevention effect can be expected.

・Symbols are changed in accordance with the difference in the applied range of evaporating temperature.

・Mainly for low and extremely low temperature equipment

Ts: temperature at element. Tʙ : temperature at sensing bulb (controlled temperature)

Ts: temperature at element. Tʙ : temperature at sensing bulb (controlled temperature)

Charging types shown in ( ) are special charging types.

| Application/Equipment \ Charging Type | G | S | (SA) | (SL) | C | (CL) |

|---|---|---|---|---|---|---|

| Relation between TS> and TB | TS>TB | TS≧TB | TS≧TB | TS≧TB | ー | ー |

| MOP Control (Overloading Prevention) | ○ | ○ | ○ | ○ | △ | △ |

| Cooling Equipment | ○ | ※2 | ○ | |||

| Low-Temperature Equipment | ※1 | ※2 | ○ | ○ | ○ | |

| Application to Extremely-Low-Temperature Equipment | ※1 | ※2 | ○ | ○ | ||

| Application to Heat Pump Equipment | ※2 | ○ | △ |

〇 means “applicable,” and △ means “may not be applicable.”

*1 : Applicable AEX only.

*2 : Depending on the M.O.P. setup.

PRESSURE EQUALIZATION TYPES

Please select external pressure equalization types for equipment with large pressure drop and fluctuation of evaporator, and internal pressure equalization types for equipment with smaller pressure drop in the evaporator.

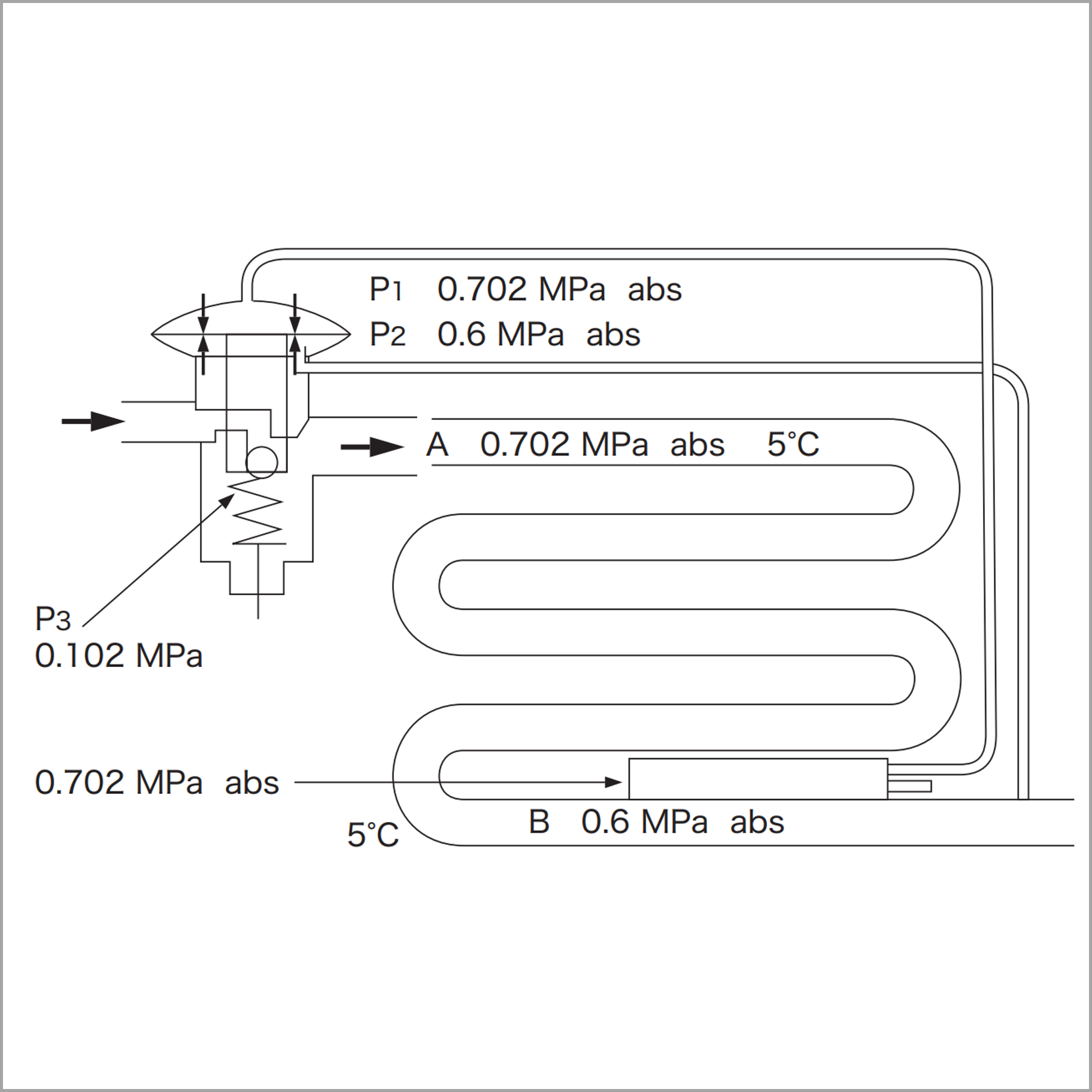

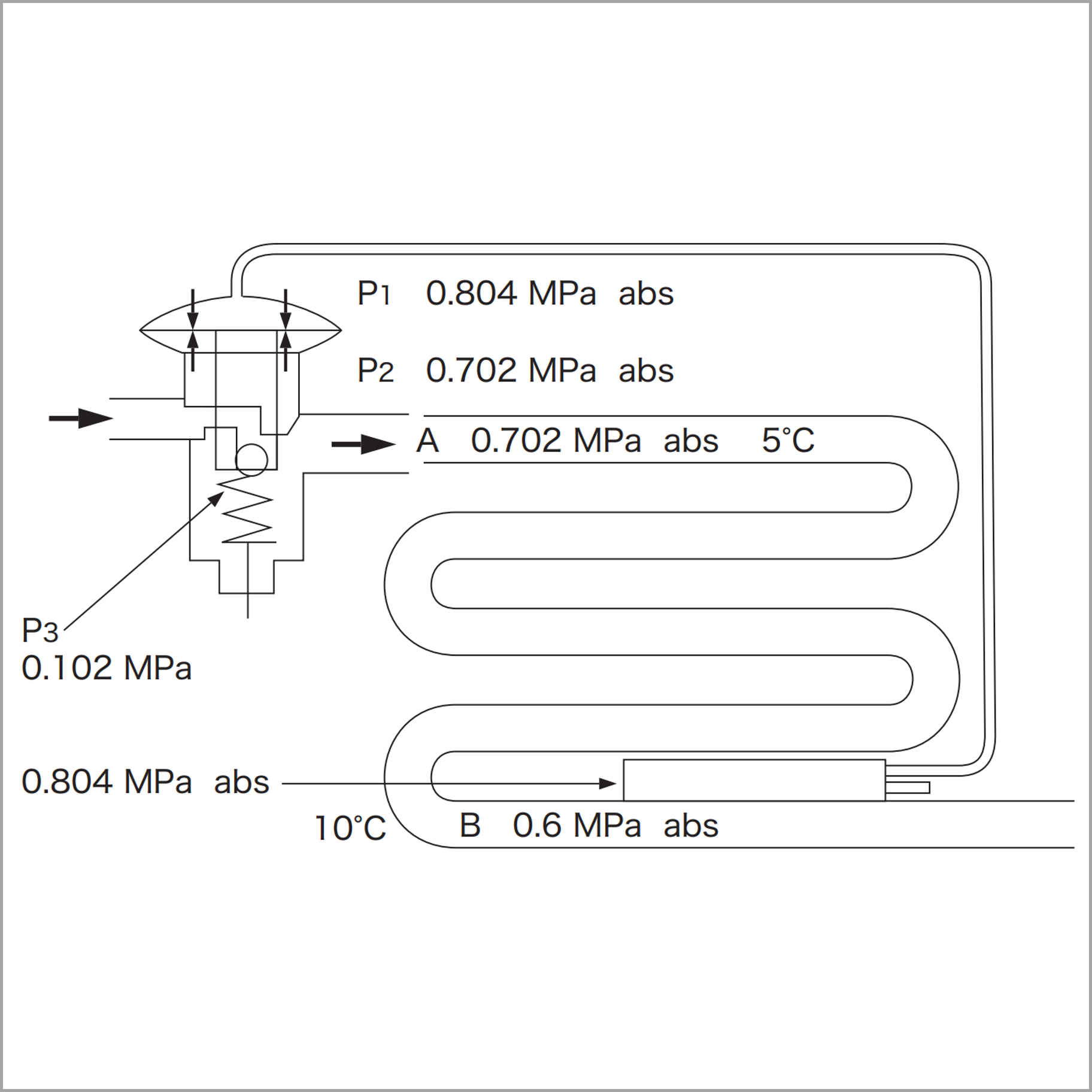

For example, when there is pressure drop of 0.102 MPa on the low-pressure side, the internal pressure equalization type will increase operating superheat approximately 5℃.

Setting :

Refrigerant R404A

Point A 0.702 MPa abs (5℃)

Point B 0.6 MPa abs (0℃)

Spring Pressure P3 0.102 MPa

External Pressure Equalization Type

External Pressure Equalization Type

Internal Pressure Equalization Type

Internal Pressure Equalization Type

Pressure in Sensing Bulb (P1)

= 0.6+0.102

= 0.702 MPa Saturation Temperature

Operating superheat is 5℃- 0℃ = 5℃.

Pressure in Sensing Bulb (P1)

= 0.702+0.102

= 0.804 MPa Saturation Temperature

Operating superheat is 10℃- 0℃ = 10℃.

PRESSURE DROP IN LOW-PRESSURE PIPING

Equivalent to pressure drop appears as an increase in operating superheat, which leads to pressure drop in suction piping and reduction of cooling capacity. Therefore, it is necessary to pay attention to excessive increases in operating superheat.

A pressure difference equivalent to 1℃ temperature difference is a guideline for the selecting pressure equalization type.

When there is a pressure difference higher than the values shown in the table bellow, is the external pressure equalization types are effective.

Pressure Difference Equivalent to 1℃ Temperature (MPa)

| Refrigerant | Evaporating Temperature(℃) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 5 | 0 | -5 | -10 | -20 | -30 | -40 | -50 | -60 | |

| R134a | 0.014 | 0.012 | 0.011 | 0.009 | 0.008 | 0.006 | 0.004 | 0.003 | - | - |

| R404A | 0.025 | 0.022 | 0.019 | 0.017 | 0.015 | 0.012 | 0.008 | 0.006 | 0.004 | 0.003 |

| R407C | 0.021 | 0.018 | 0.016 | 0.014 | 0.012 | 0.009 | 0.006 | 0.004 | 0.003 | 0.002 |

| R410A | 0.033 | 0.029 | 0.026 | 0.023 | 0.020 | 0.015 | 0.011 | 0.008 | 0.006 | 0.004 |

| R448A | 0.022 | 0.020 | 0.017 | 0.015 | 0.013 | 0.010 | 0.007 | 0.005 | 0.003 | 0.002 |

| R449A | 0.022 | 0.019 | 0.017 | 0.015 | 0.013 | 0.010 | 0.007 | 0.005 | 0.003 | 0.002 |

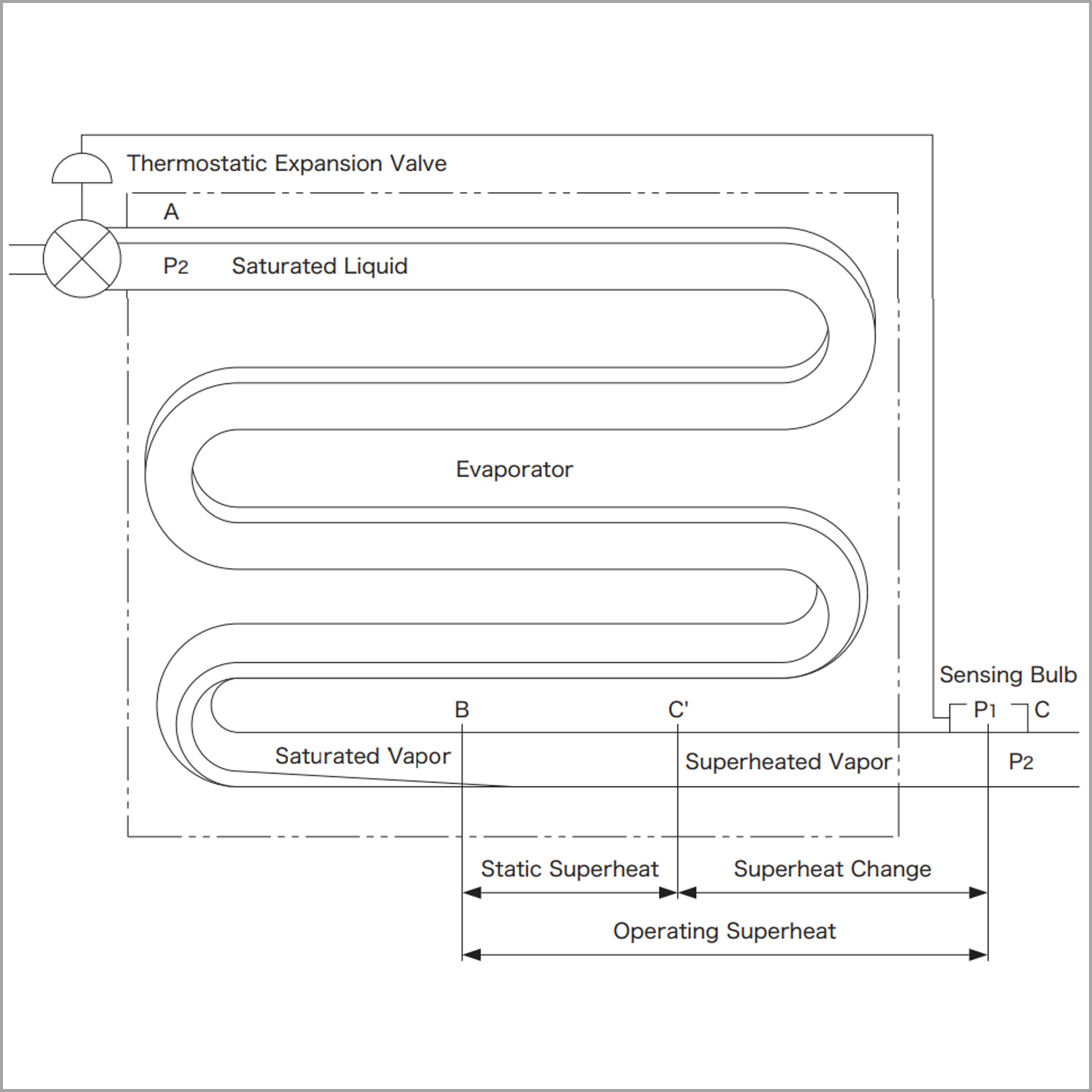

SUPERHEAT

The degree of temperature increase, without a change of pressure, against the saturated vapor temperature of the refrigerant. Expansion valve superheat has static superheat (SSH) and superheat change (SHC), and the sum of SSH and SHC is the operating superheat (OSH), which is equivalent to the degree of superheat generated at the evaporator outlet.

Operating Principle of Superheat

Static Superheat (SSH) : Superheat from valve closing position to valve opening

Superheat Change (SHC) : Superheat from valve opening to required flow rate

Operating Superheat (OSH) : Static Superheat + Superheat Change

Static Superheat Adjustment

Adjustment of superheat means the adjustment of static superheat.

Please set the static superheat for the safety of equipment unless there is a specific reason.

| Adjustable Range of Static Superheat(℃) | Amount of Change per Spindle Rotation (MPa) | |

|---|---|---|

| QCX RCX |

1~5(R410A) | Approx. 0.045 |

| 1~7(R448A, R449A) | ||

| SCX | 1~5(R134a, R404A, R448A, R449A) | |

| 1~7(R407C, R410A) | ||

| AEX | 0~20 | Approx. 0.05 |

| ATX | 1~7((R410A, S, SL charge for R404A) | Approx.0.007 |

| 0~8(S, SL charge) | ||

| 0~10(C charge for R448A, R449A) |