Test Systems

Japanese-made Products Continue to Accommodate the Needs of a Diverse Global Market

In today's world, society and industry have learned to ask more from the products they create and consume. In addition to convenience, performance, and quality, products must also deliver on environmental considerations, energy efficiency, as well as other complex factors.

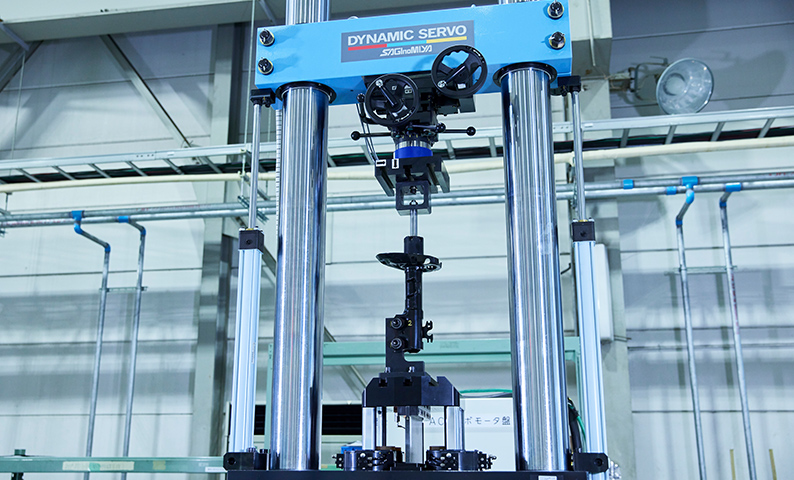

Saginomiya's "Dynamic Servo" line of test system draws from our extensive expertise and track record in actuator control technology, leveraging characteristics from hydraulic, pneumatic, servo motor, linear motor, and other systems, along with our hallmark digital twin technology. These innovations maximize the speed and efficiency of the development process for our customers.

Our "Dynamic Servo" line is constantly expanding into new educational and research institutions as well as global markets, spanning automobile manufacturing, construction, civil engineering, food products, industrial machinery, railways, electrical engineering, precision equipment, and even the aerospace industry. We pride ourselves on being one of the few manufacturers to provide comprehensive test system on a global scale. We are dedicated to offering each customer optimal solutions tailored to their needs and industry.

Overview

-

Development and Sales of Test system

Saginomiya develops and distributes a diverse array of test systems and products, ranging from driving simulators to hardware-in-the-loop systems, performance testing, and durability test system. These are adapted to meet our customers' needs at every stage of the manufacturing process, from initial design through prototyping to mass production.

Our Strengths

-

01Exceptional Actuator Technology and Refined Control

Saginomiya's "Dynamic Servo" lineup represents the pinnacle of actuator technology, offering diverse options including hydraulics, pneumatics, servo motors, linear motors, and other technologies. By combining our propriety digital servo controllers with a rich array of software applications, we provide top-quality and customizable options for every testing scenario.

-

02Adapting to Diverse Needs in Manufacturing

The trust we have built over the sixty-year history of our Dynamic Servo line has spread far beyond the automotive industry. We offer the latest in technology to meet the demands of a multitude of industries with our high-speed materials test systems for metals and resins, micro-load fatigue test systems, large-scale multi-axis vibration tables for civil engineering and construction, high-speed load-bearing actuators, 25MN seismic isolation rubber testing, among others.

-

03Global Expansion

Over 660 of our Dynamic Servo systems have been installed in twenty-two countries throughout the world, mainly in Asia, Europe, and the United States. To respond to recent rapid market changes, Saginomiya has established new sales offices at two locations in the Western Hemisphere in addition to our four Asia-based locations, expanding our global presence to six sales and maintenance service centers. This enables us to meet the needs of our customers worldwide.

Markets for Test Systems

-

Mobility

The aim of mobility is to support the sustainable development of cities through advancing diverse transportation systems. Saginomiya prides itself on providing solutions to issues in safety, efficiency, and environmental impact reduction, among others, by providing cutting-edge technology and products for the automobile, railway, and aviation industries.

-

Infrastructure

Saginomiya offers a variety of test system and experimental tools with servo technology to simulate large-scale seismic activity. This allows us to provide the best possible device evaluations for equipment related to research on earthquake-resistant building technology, paving the way for infrastructure that will be able to outlast major earthquakes in the future.

-

Materials

Industrial goods come with innumerable requirements and use-case scenarios. In addition to Saginomiya's best-selling "High-Speed Material Test System Load Sensing Block Type" and "Micro Load Fatigue Test System," we can manufacture equipment to test a range of metals, plastics, composites, ceramics, and other materials. We are also able to adapt these systems to reproduce our customers' specified environmental conditions, including extreme temperatures, hydrogen embrittlement, and more.