Saginomiya Technical Laboratory

Saginomiya Technical Laboratory

Opening Soon!

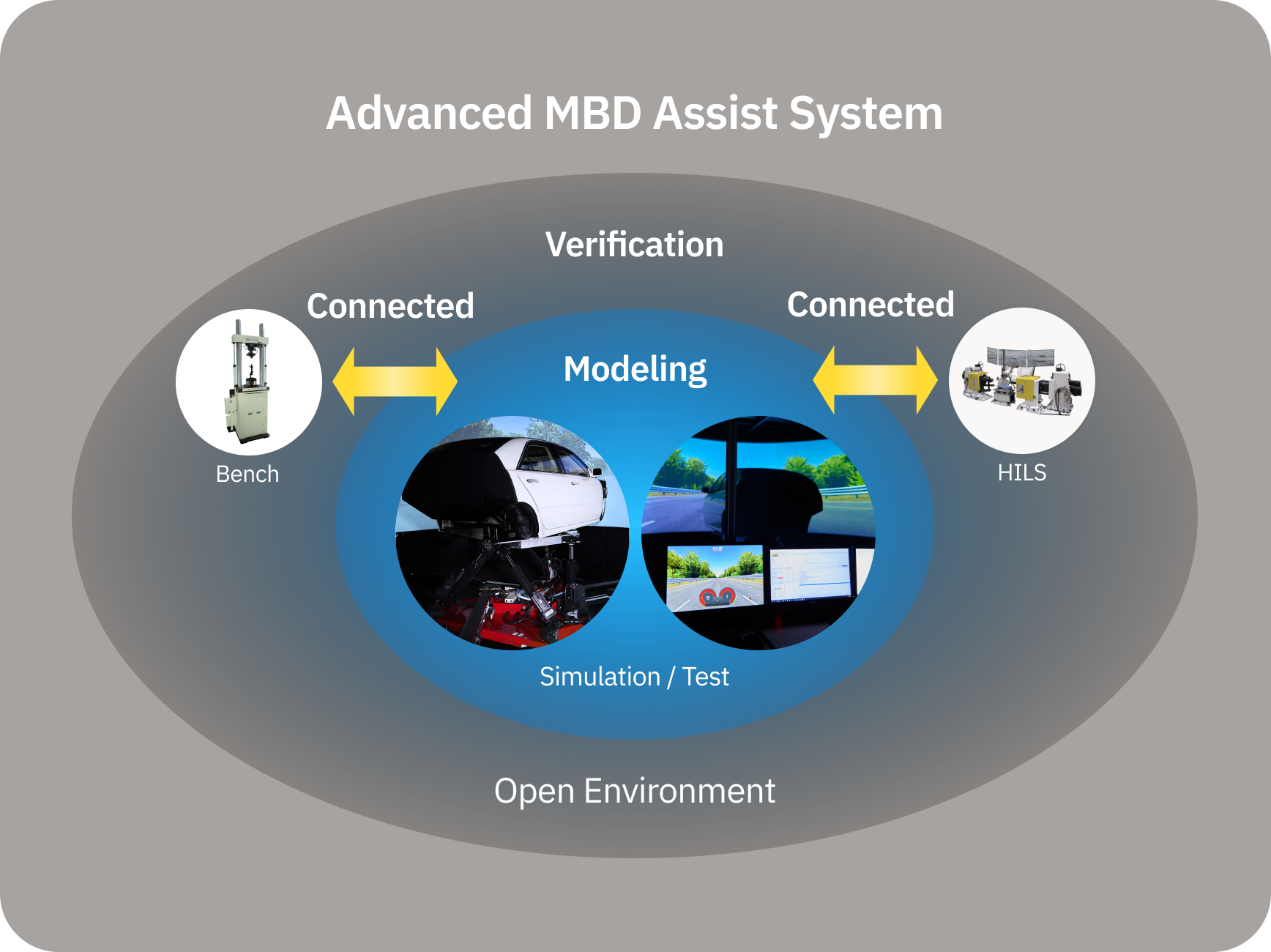

Cutting-Edge Technology Testing Facility to Assist with Model-Based Design

The Saginomiya Technical Laboratory is outfitted with the latest in technology, from our DiM driving simulators to hardware-in-the-loop (HIL) test systems. Our tests can be used to assess driverless cars while they are still in the design phase by measuring stability and ride comfort. By connecting our HIL systems with the driving simulators, customers can also get compatibility feedback on individual components for driverless vehicles. In addition, we have a wide range of advanced performance test equipment and general-purpose durability testing machines, allowing our expert engineers to meet diverse testing needs. Our expert engineers are trained to run a diverse range of tests to meet our customers' needs, in addition to conducting standard performance and durability analyses. Saginomiya is a leading contributor to the rapidly evolving world of Model-Based Design, offering state-of-the-art testing labs to streamline and accelerate the vehicle design process.

Features of the Saginomiya Technical Laboratory

-

01Immersive Product Demonstrations

Dive into Saginomiya's latest digital twin technology by experiencing first-hand the DiM150 and DiM300 driving simulators and accompanying hardware-in-the-loop simulations.

-

02Customer Service for Commissioned Evaluations

Saginomiya is able to accommodate a diverse set of criteria based on our customers' needs. Our test systems is designed specially to measure fatigue characteristics for individual materials or assembled products as well as their static and dynamic characteristics and other properties. Those interested may schedule a remote video conference in order to see how contract work is carried out in more detail.

-

03Streamlining the Vehicle Development Process

Reach out to our support team to help accelerate your vehicle development process.

Equipment

Rent our on-site DiM150 and DiM300 driving simulators and get swift feedback from our expert motion cueing engineers about driving characteristics, ride quality, AD/ADAS analysis, and other assessments that cater to distinct use-case scenarios. Component compatibility can also be tested by merging data sets with our hardware-in-the-loop simulations. Demo test drives are available for customers considering incorporating these products into their development process.

DiM Driving Simulators

The Driver-in-Motion®, or "DiM" simulator, is the latest of its kind, providing a "real-time" immersive experience of vehicle dynamics while a car model is still in early development, streamlining and accelerating the testing phase.The DiM's combined Hexapod and Tripod configuration and innovative "floating" system are the keys to its stellar performance as a motion platform simulator.

DiM300 at the Saginomiya Technical Laboratory

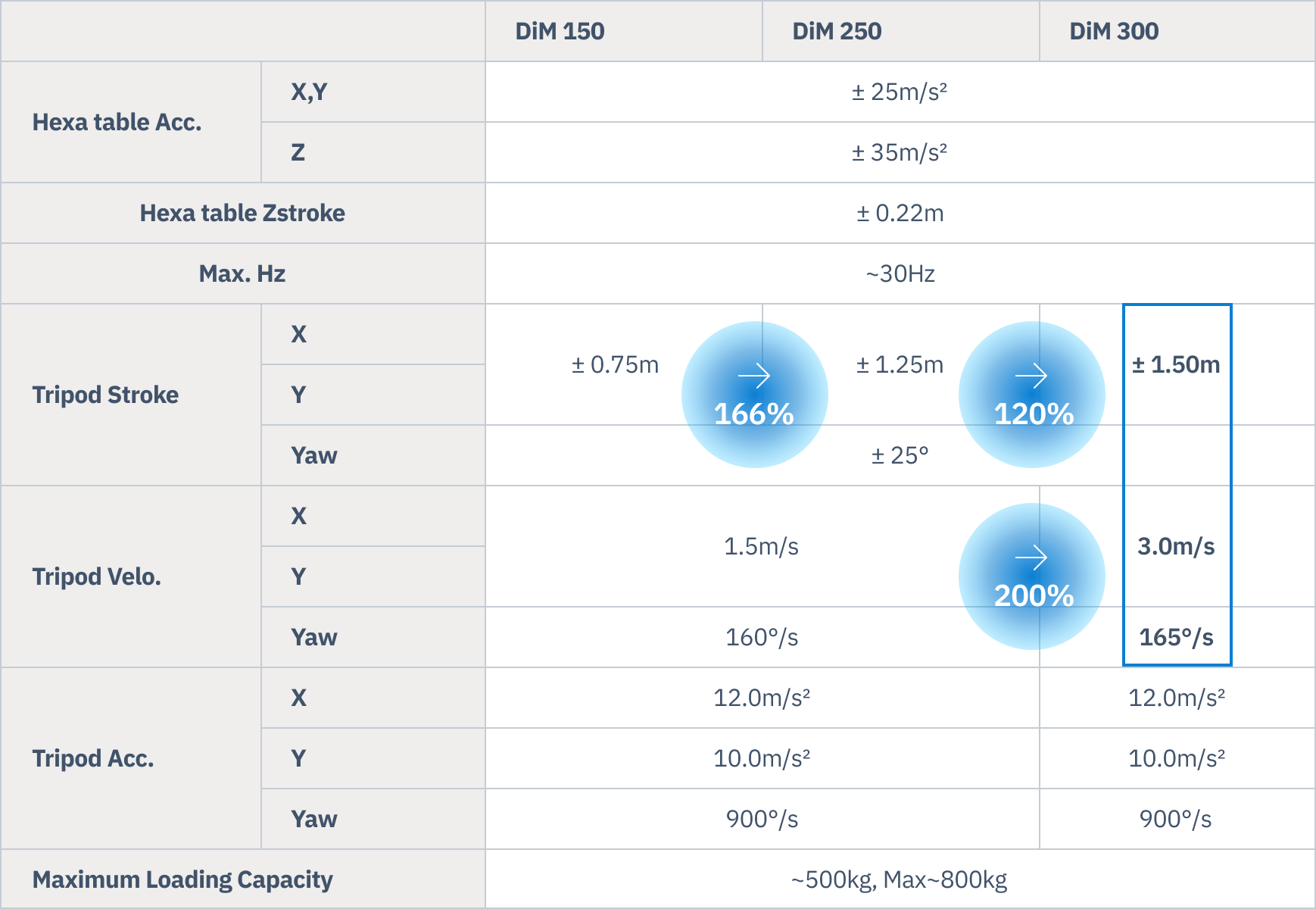

Updated Specifications for Next-Level Responsiveness

*Tripod: Acceleration 1G, Velocity 3.0m/s

*Tripod: Acceleration 1G, Velocity 3.0m/s

State-of-the-Art Concept to Introduce Increased Immersion

-

Full Carbon Fiber Cockpit

Light-weight and robust construction for improved accuracy

-

Additional Human-Machine Interfaces

Freely interact with computer and monitor interfaces

-

Fully-Active Seat

Feel like you're there with realistic seat vibrations, belt tension, and pneumatic press technology

Other Featured Equipment and Systems

-

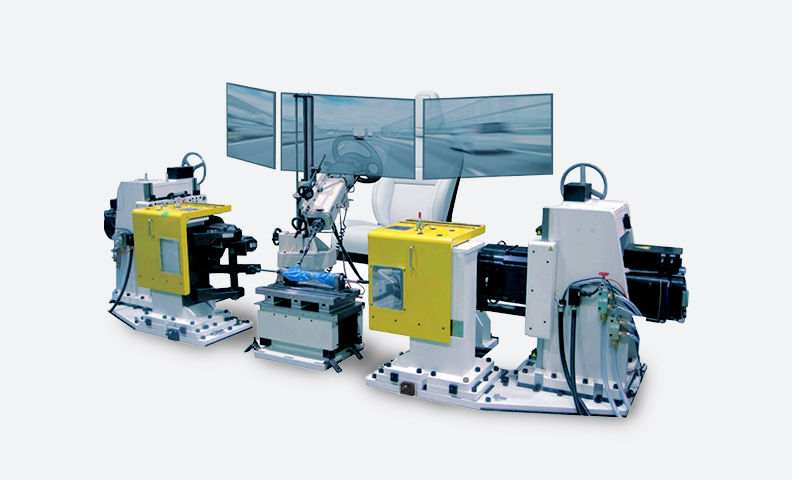

CRH Steering Test System with HIL Simulation

Equipped with highly responsive linear actuators, this system allows the user to pair a prototype vehicle with a digital twin to conduct performance evaluations on steering systems and fail-safes for by-wire technology from the safety of a testing rig. Demos are available for customers considering incorporating this system into their development process

-

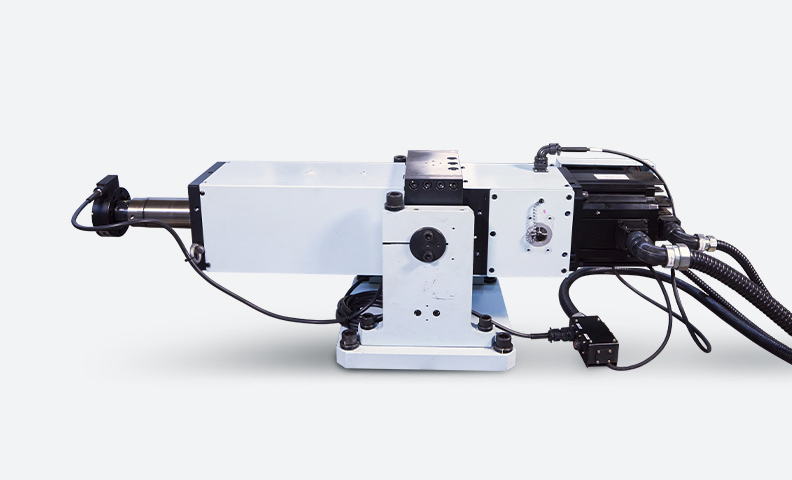

ASH Linear motor type Absorber Test System

This system was developed with our in-house high-performance linear actuators, which offer vastly improved low-speed waveform distortion rates, a notorious issue for conventional hydraulic servos. The system can also obtain highly accurate broadband damping data covering everything from minute displacements and microloads to large amplitudes and heavy loads. Any customer looking to upgrade or expand upon their hydraulic servo test system is welcome to try this technology for themselves first-hand.

-

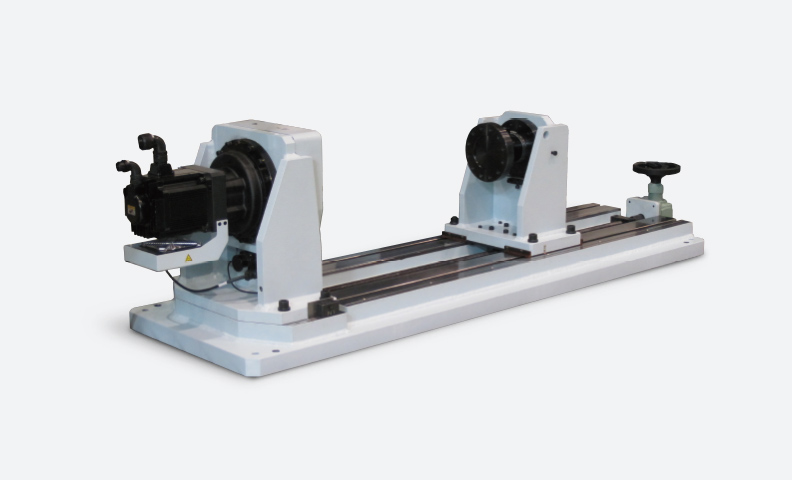

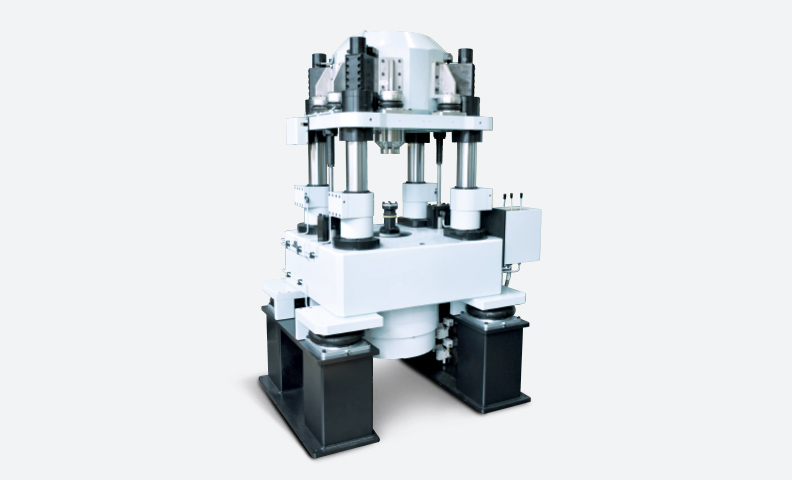

RFH Electric Servo Torsional Test System

Utilizing highly energy-efficient electric servo actuators, this system is capable of fatigue and fracture testing on a variety of transmission components, including round rods and constant velocity joints. Any customer looking to upgrade or expand upon their hydraulic servo test system is welcome to demo this technology.

-

KCH 3kHz Elastomer Test System

This system makes use of high-frequency compatible electrodynamic actuators which can measure a variety of properties. Examples include static spring characteristics and dynamic attributes up to 3kHz for both conventional and electric vehicle engine mounts, as well as assessments for center bearings and engine mount bushings. Customers looking to introduce this technology into their development process may demo this equipment to see how it performs first-hand.

-

LFH Electric Servo Fatigue Test System

This system is designed for general-purpose linear fatigue testing, as well as recreating realistic fatigue scenarios using surface plates and angle plate blocks for components of varying shapes and sizes. The system employs highly energy-efficient electric servo actuators. Any customer looking to upgrade or expand upon their hydraulic servo test system is welcome to demo this technology.

Contact Us Regarding Commissioned Evaluations

If you have any questions or need more information about contracting us to use these systems, please reach out.